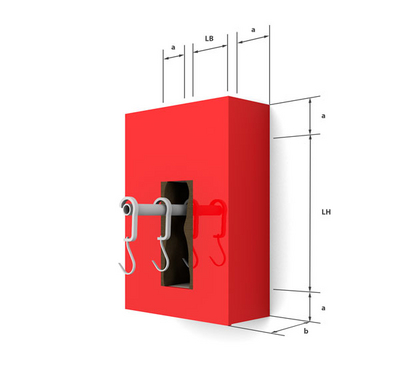

Product description

-Intumescent sealing system

-No clearing of the closing area required if the conveyed material is non-combustible

-No moving sealing elements

Small space requirements on the wall plate

Tested to EI 90 according to DIN EN 1634-1 with conveyed material "fully loaded bottle conveyor"

Type | Fire protection closure as part of track-bound conveyor systems |

Closing direction | Intumescent swelling on all sides |

Fire resistance | EI1 90 • tested according to DIN EN 1634-1 |

Closing cycles | Not required, because there are no moving parts |

Re-opening | not required |

Conveyor system | Continuous roller conveyor system • Continuous suspension chain conveyor • Continuous belt conveyor system • Circular conveyor |