Product description

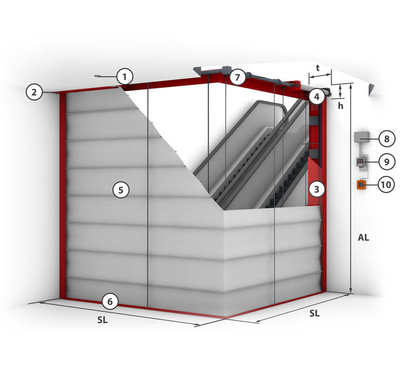

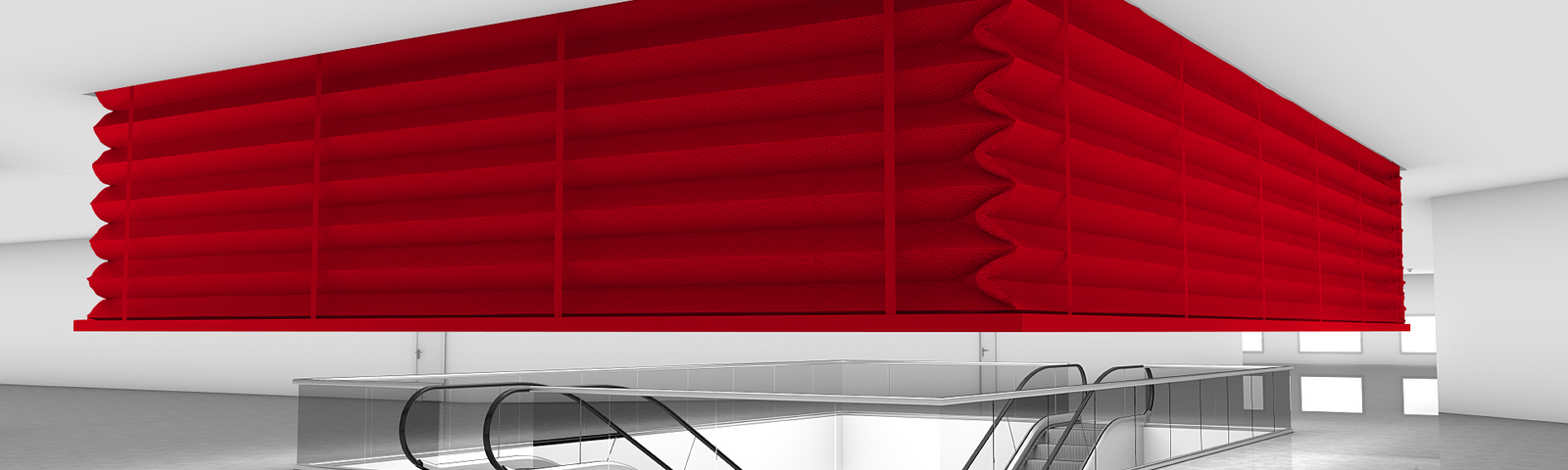

Fire protection that leads around corners: The floor space of the closure can be realised in a rectangular and polygon-shape with angles between 30° and 150°. No support elements are required despite the corner design. In addition to a closed polygon shape, open systems can also be realised that close against the wall by installing special guide rails. The fire protection curtain can be closed without any external energy by means of the 'Gravigen' drive system that is included as standard. The Fibershield-S complex allows for complex sealing geometries to be realised, while also complying with the requirement of closing off a space for more than 90 minutes.

Type | Textile fire protection curtain |

Achievable protection goals | EI - with fire load free zone • EW 90 • EI - with sprinklers |

Fabric | Ecotex 1100 A2 • Heliotex |

Fire load free zone | Protex/Ecotex: EI 30/60/90min 100/150/200 cm • Heliotex: EI 30/60/90min 20/30/50 cm |

Verification | IBS 08062416 • UL 10 (b) (2009) • UL 10 (c) (2009) • UL 10 (d) (2009) • NFPA 252 (2012) |

Closing direction | From top to bottom |

Closing cycles | C1 |

Fabric | System width | Drop length (AL) | t | h |

|---|---|---|---|---|

Ecotex 1100 A2 | < 50 m | < 3 m | 490 mm | 125 mm |

Ecotex 1100 A2 | < 50 m | > 3 m - ≤6 m | 490 mm | 225 mm |

Heliotex EW 90 | < 50 m | < 2.2 m | 490 mm | 125 mm |

Heliotex EW 90 | < 50 m | > 2.2 m - ≤2.5 m | 490 mm | 225 mm |

Heliotex EW 90 | < 50 m | > 4.5 m - ≤6 m | 490 mm | 450 mm |

Special

References