Product description

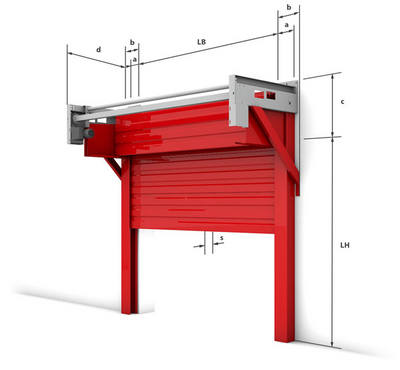

Space-saving and extra sturdy sheet metal closure for discontinuous and separate conveyor systems: Omnicompact features a segmented damper blade. This stacks up into the lintel area during closing. The system is suitable for very large openings, but is also available as a low-camber version that just requires a height of 560 mm. Omnicompact complies with the requirements of fire resistance classes EI 30 to EI 120 (tested according to DIN EN 1634-1) and is approved as a T30 and T90-gate.

Type | Vertical fire protection stacking door |

Closing direction | From top to bottom |

Fire resistance | T 90 • EI1 120 • tested according to DIN EN 1634-1 |

Re-opening | electromotive (standard) |

Conveyor system | Interrupted conveyor system • Continuous conveyor system • Continuous roller conveyor system • Continuous suspension chain conveyor • Continuous travelling carriages |

Downloads

Required wall quality | |

|---|---|

masonry | d ≥ 240 mm |

concrete | d ≥ 140 mm |

aerated concrete | d ≥ 200 mm |

reinforced aerated concrete | d ≥ 200 mm |

Technical feasibility | |

|---|---|

LH | (T30) 2000 mm - 6000 mm |

| (T90) 2000 mm - 4500 mm |

| (EI90) 2000 mm - 6400 mm |

| (EI120) 2000 mm - 4300 mm |

LW | (T30) 1000 mm - 9000 mm |

| (T90) 1000 mm - 4500 mm |

| (EI90) 1000 mm - 6700 mm |

| (EI120) 1000 mm - 4500 mm |