Product description

The sheet metal damper is characterised by its robust sandwich construction with sheet metal casing on all sides. It is suitable for interrupted and continuous conveyor systems such as belt, roller and suspension chain conveyors. Segmented damper elements enable smooth conveyance to the installation site. Variable fixed panels provide for easy implementation of customer-specific solutions.

Type | Fire protection closure as part of track-bound conveyor systems |

Proof of usability | European Technical Assessment - ETA |

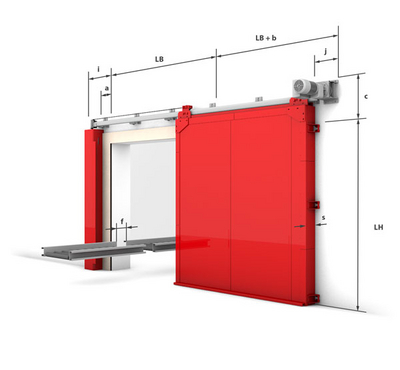

Closing direction | from left to right • from right to left • From top to bottom |

Fire resistance | EI1 120 |

Closing cycles | C5 number of closing cycles 200,000 • classified according to DIN EN 13501-2 |

Re-opening | electromotive (standard) • manual |

Conveyor system | Skid conveyor • Sloping track • Interrupted conveyor system • Continuous belt conveyor system • Continuous travelling carriages • Continuous suspension chain conveyor • Continuous roller conveyor system • Continuous conveyor system |

Required wall quality | |

|---|---|

Masonry | d ≥ 200 mm |

Concrete | d ≥ 200 mm |

Aerated concrete | d ≥ 200 mm |

Assembly walls | d≥ 160 mm |

panelled steel construction | acc. to DIN 4102-4 |

approval range (max 13.6sqm) | |

|---|---|

LW | 4500 mm |

LH | 4500 mm |

technical feasibility | |

|---|---|

LW | 4500 mm |

LH | 5100 mm |

Required wall quality | |

|---|---|

Concrete | d ≥ 200 mm |

Masonry | d ≥ 200 mm |

aerated concrete | d ≥ 200 mm |

assembly walls | d ≥ 160 mm |

panelled steel construction acc. to | DIN 4102-4 |

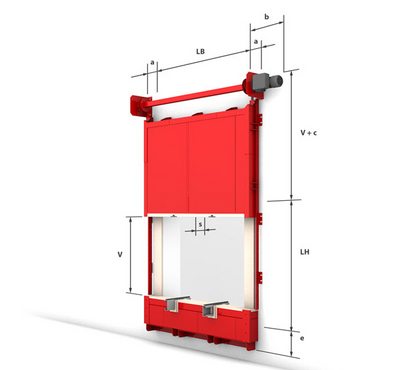

approval range (12.1 m² vertical closing direction) | |

|---|---|

LW | up to 4500 mm |

LH | up to 4500 mm |

technical feasibility (max. 20.25 m²) | |

|---|---|

LW | up to 4500 mm |

LH | up to 5100 mm |