Product description

In case of alarm self-closing, thermally insulating

fire protection closure of textile construction in vertical installation position and closing direction.

Type | Heat-insulating fire protection closure with textile design |

Verification | CE identification pursuant to EN 16034:2014 in conjunction with EN 13241:2003+A2:2016 |

Closing direction | From top to bottom |

Fire resistance | EI1 30 - EI2 120 • tested according to EN 1634-1: 2014-03 • Classified according to EN 13501-2:2016 |

Smoke protection | Classified according to EN 13501-2:2016 |

Closing cycles | C • C1 • C2 • tested according to EN 12605 : 2000-08 • Classified according to EN 13501-2:2016 |

Fire behaviour of textile | B-s1, d0; E-d2 • Tested according to ISO 11925-2 and EN 13823 • Classified according to EN 13501- 1:2018 |

Environmental conditions | Special environmental conditions are not taken into account (e.g. humidity > 80 %, ambient temperature < 5 °C and > 45 °C, wind loads etc.). |

Visible surfaces | coated in RAL, NCS standard colour, stainless steel V2A material A-1.3401 |

Downloads

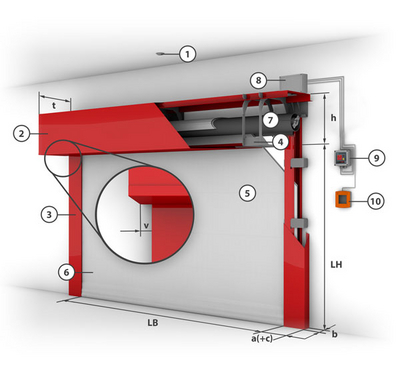

1Smoke detector2Housing3Guide rails4Attachment bracket5Fabric6Closing element7Tubular motor8Control module9Control with operating unit10Manual release

Classification | Size max. [LB x LH] in mm | Wall thickness* | Housing | Guide rail [a (+c) x b] |

|---|---|---|---|---|

EI130 | 7315 x 4950 | 150 mm | Type A or Type B | Type 1 or Type 3** |

EI230 | 7315 x 4950 | 150 mm | Type A or Type B | Type 1 or Type 3** |

EI160 | 6600 x 4840 | 150 mm | Type B | Type 2 |

EI260 | 6600 x 4840 | 150 mm | Type A or Type B | Type 1 or Type 3** |

EI190 | 6000 x 4400 | 150 mm | Type B | Type 2 |

EI290 | 6000 x 4400 | 150 mm | Type B | Type 1 |

EI2120 | 6600 x 4840 | 175 mm | Type B | Type 2 |

C2 | 6600 x 4840 | |||

Sa | Joint length 14.5 m |

* The wall can be low density (aerated concrete block) or high density (masonry or concrete). ** Type 3 guide rails – maximum size 3000 x 2870 mm

Casing installation options

References