Product description

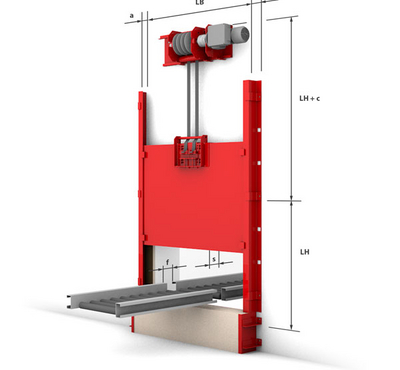

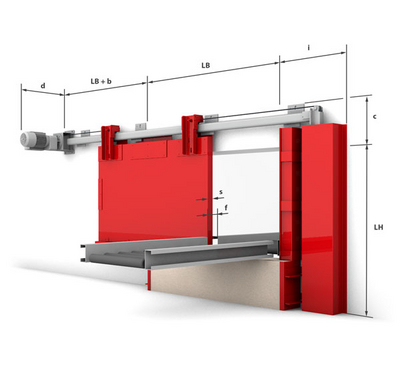

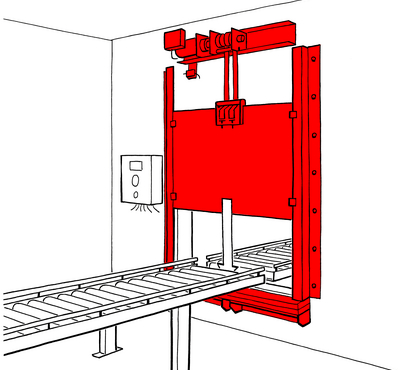

The Global Conveyor Closure (GCC) is a compact conveyor system closure in element design for separate and continuous conveyor systems. It only requires a small overlap on the wall surrounding the opening. For discontinuous conveyor systems, just a short interruption of the conveying line (separation point) is necessary thanks to the very slim sheet metal of the damper. There is a wide range of surface design options for the sliding damper - from the cost-efficient basic version made of untreated fire protection plates to surfaces coated with emulsion paint or to high-quality cladding of the damper with galvanized steel sheet (optionally powder-coated or in stainless steel).

Type | Fire protection closure as part of track-bound conveyor systems |

Proof of usability | European Technical Assessment - ETA |

Closing direction | From top to bottom • from left to right • from right to left |

Fire resistance | EI1 30 • EI1 60 • EI1 90 • tested according to DIN EN 1366 |

Closing cycles | C5 number of closing cycles 200,000 |

Re-opening | electromotive (standard) |

Conveyor system | Interrupted conveyor system • Sloping track • Continuous belt conveyor system • Continuous travelling carriages • Continuous roller conveyor system • Continuous suspension chain conveyor |

Downloads

Required wall quality | |

|---|---|

Masonry | d ≥ 150 mm |

Concrete | d ≥ 150 mm |

Aerated concrete | d ≥ 150 mm |

Panelled steel structure | according to DIN 4102-4 |

Approved range (max 10,08 m²) | |

|---|---|

LW | 3600 mm |

LH | 4200 mm |

Technical feasibility | |

|---|---|

LW | 3600 mm |

LH | 4200 mm |