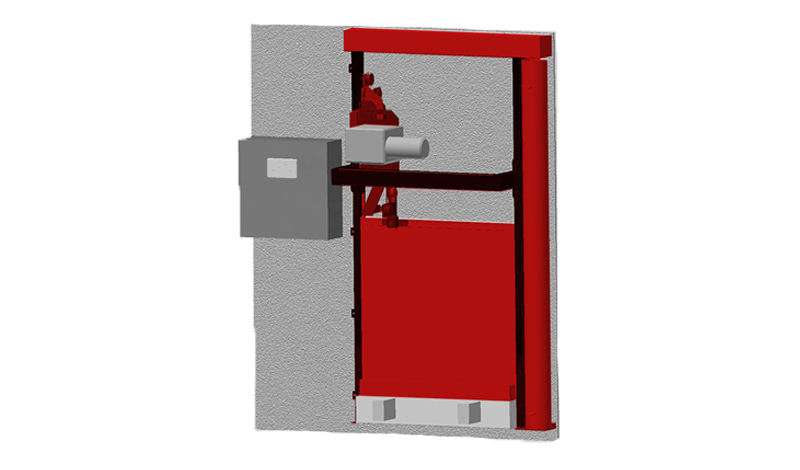

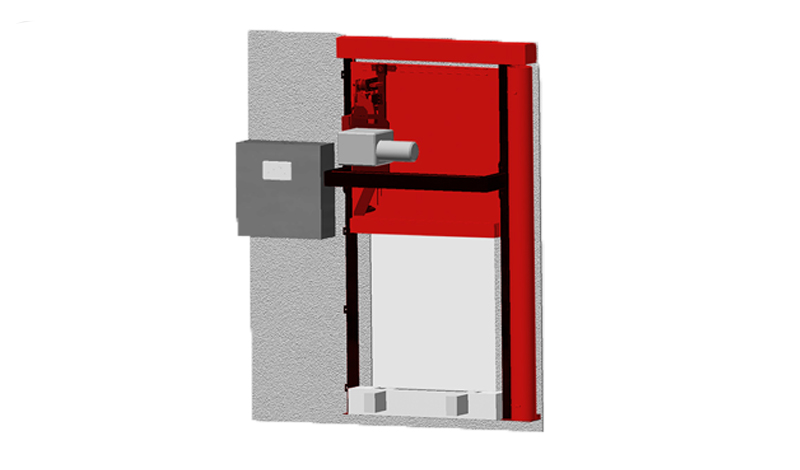

SYSTEM: BR 100 (ALSO WITH FAST RUNNING FUNCTION)

| Type | Fire protection closure in the course of rail-bound conveyor systems |

| Verification | ETA-16/0851 European Technical Assessment (BR 100 EU) | Z-6.6-2089 General building authority approval/general type approval (BR 110 D) | VKF Technical Information No. 32801 (BR 100 E) |

| Closing direction | from top to bottom | from bottom to top | from left to right | from right to left | horizontal double leaf closing to the centre |

| Fire resistance | Until EI2 90 | tested according to EN 1366-7:2004 | classified according to EN 13501-2:2007 |

| Closing cycles | Until C5 | 200.000 closing cycles | classified according to DIN EN 13501-2:2007 |

| Reopening | motorised or manual |

| Conveyor systems | Belt conveyor technology | Suspension chain conveyor technology | Roller conveyor technology | Electric monorail system | Power & Free |

| Visible surfaces | Galvanised, RAL |

Size dimensions and system structure

The specifications of the individual product versions with regard to classification, system size and required wall quality of the BR 100 series can be found in the respective data sheets.

The installation situation must comply with the building regulations of the country of installation. The fire resistance of a ceiling or wall supporting structure and the neighbouring components must at least correspond to that of the fire and/or smoke protection closure/fire and/or smoke protection curtain. Proof of the stability and serviceability of the neighbouring walls and components must be provided under general ambient conditions and in the event of fire. See also notes on the standard load-bearing structure in EN1366-7:2004 or EN1363-1:2020. The fire protection system must not be exposed to any additional load other than its own weight, even in the event of a fire.