Product description

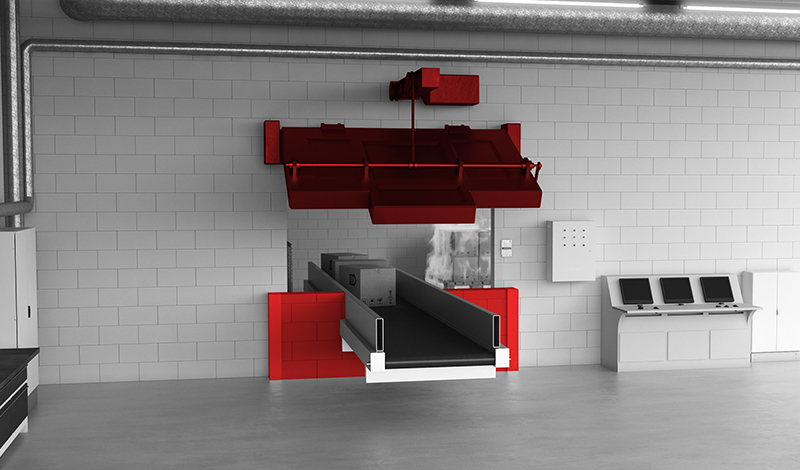

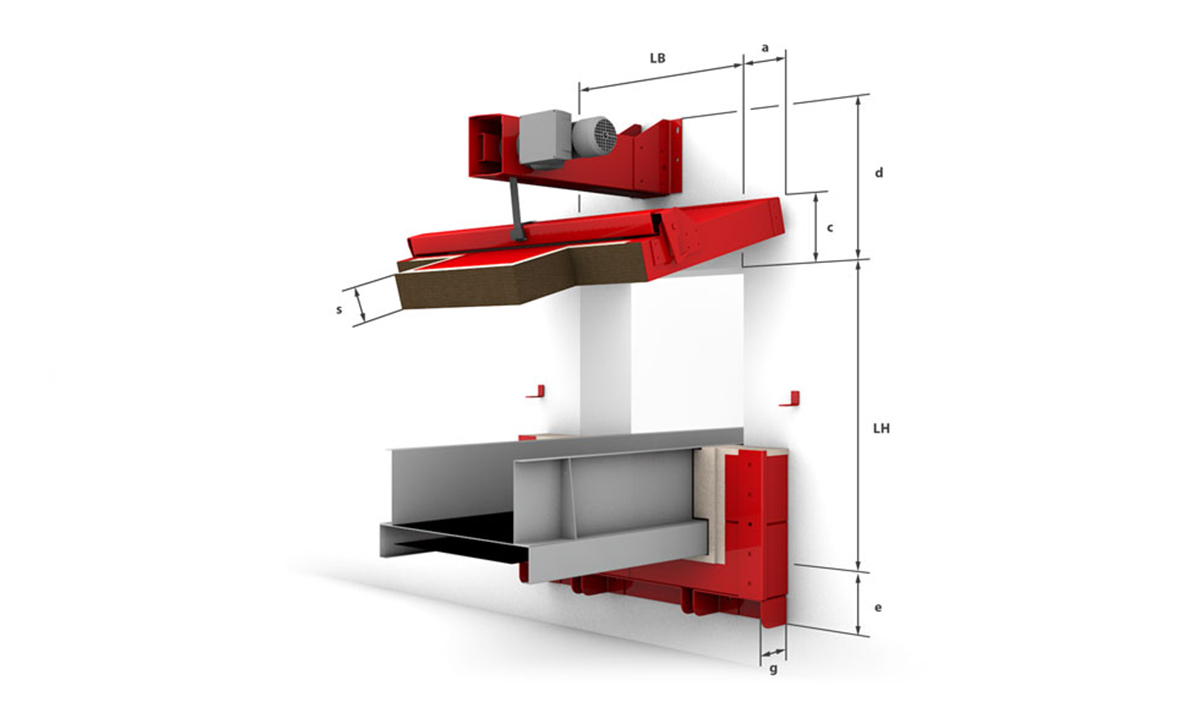

The horizontally slewing damper construction requires very little space in the lintel area and is therefore an interesting option for conventional closures in damper design. ECClos®-Q meets the requirements of classifications EI 30 to EI 120 and EW 240 (aerated concrete). The damper blade features a very stable sandwich construction and is completely enclosed by a sheet metal casing. ECClos®-Q is suitable for continuous and separate conveyor systems, such as baggage belt conveyors. For continuous conveyor systems, the fixed panel is customised and the surface can be designed according to customer requirements in various designs.