Fire protection for electricity storage systems

Lithium-ion batteries, cells and rechargeable batteries power electric cars, e-bikes, e-cigarettes, smartphones and more. Compared to other battery technologies, these special energy storage devices have a particularly high energy density.

In principle, lithium-ion technology is safe, but under certain circumstances, the batteries can fail, i.e. explode. In such a case, violent reactions occur in the form of fires, during which toxic and corrosive harmful gases are emitted. The high temperatures can also be dangerous for people and property.

We would like to clarify the possible causes and present our safe transport and storage solutions for lithium-ion batteries from the product series StrainBox.

Even a single small button cell in residual waste can trigger a major fire, e.g. from a carelessly discarded music greeting card. As the ➥ FAZ reports, fires worth millions occur time and again in waste disposal companies. This is why it is so important to always dispose of batteries and rechargeable batteries properly.

Why do batteries fail?

Lithium-ion batteries can self-ignite under certain conditions. In this case, we speak of an accident or thermal runaway - the battery overheats and "thermally burns out". The reasons for this can come from outside (external) or from the battery itself (internal), through a self-reinforcing heat-producing process.

* The separator is the inner separating layer between the anode and cathode, which is intended to prevent uncontrolled charge exchange.

What happens during a thermal runaway?

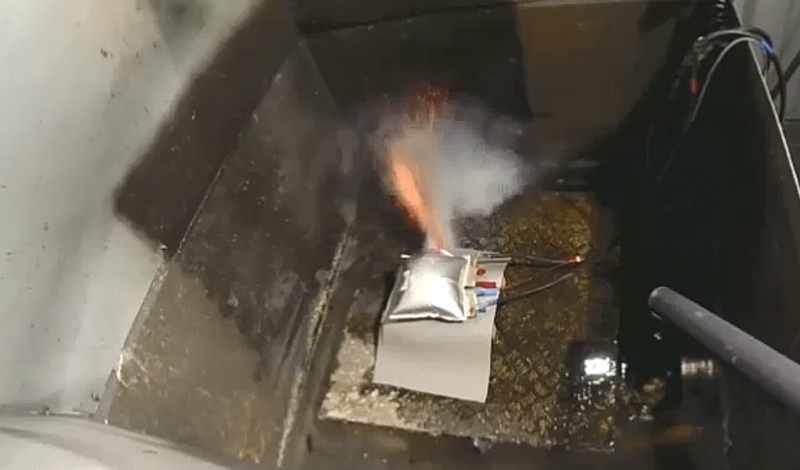

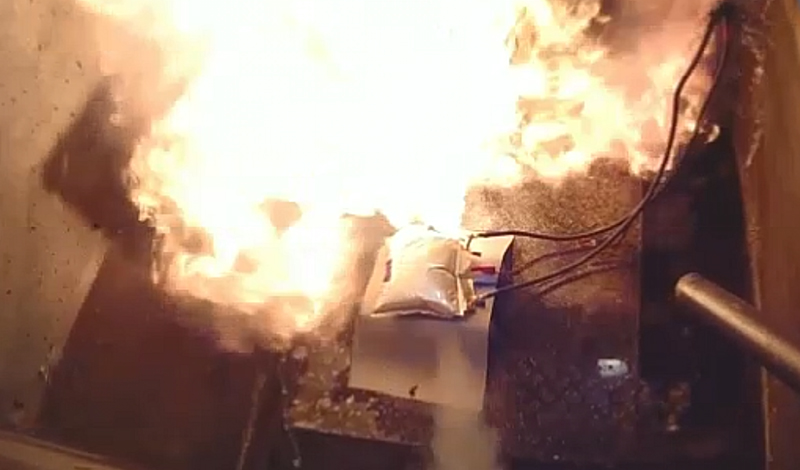

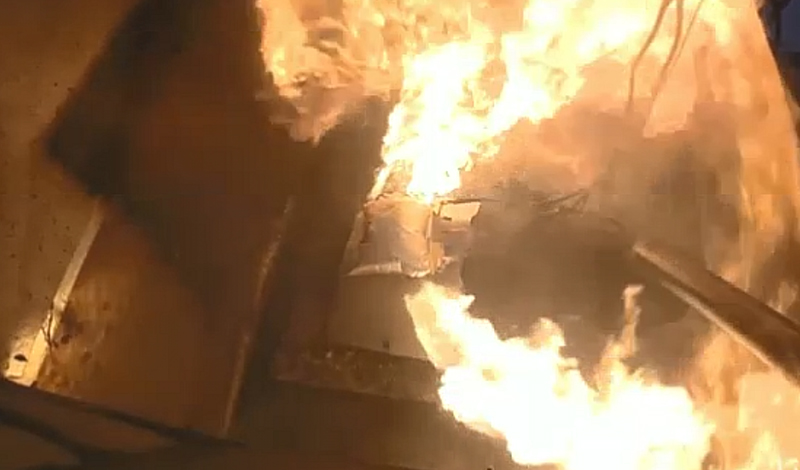

It can happen that quickly: A battery ignites within a few seconds. We regularly carry out fire tests with lithium-ion batteries under real conditions in the test centre at the STÖBICH North site. In the short video you can see the four different stages of a classic battery fire.

Tested in the test centre

As part of our product development, we regularly check the safe function of our storage and transport boxes. We also support customers in planning, carrying out, documenting and analysing their own tests. The tests take place in our in-house battery test centre, where products for the safe handling of lithium-ion batteries are tested in addition to battery tests.

ADR: Legal regulation for battery transport

Our transport boxes must be ADR-compliant, i.e. approved for the safe transport of dangerous goods by road: in accordance with the Agreement concerning the International Carriage of Dangerous Goods by Road (ADR).

Burning electric cars are a regular topic in the media. There is often talk of a "technical defect" as a possible cause of the fire, such as the ➥ fire in an electric post office vehicle in Pirmasens.. Whether it is a battery fire can usually only be clarified later in the course of the investigation. Due to the potential danger described above, a connection between the energy storage system and the fire is relatively likely.

What to do with the damaged battery?

Even after a battery fire has been extinguished, the danger is far from over: What to do with the contaminated extinguishing water and the defective energy storage unit itself? The legal situation is not clear, and fire brigades are not officially responsible for the transport and disposal of damaged batteries. Nevertheless, the fire service can keep battery safety systems on hand for use - which makes sense given the increasing number of fires involving modern battery technologies.

We at STÖBICH have handed over several StrainBoxes to the Goslar fire service. For space reasons, we store the largest StrainBox XL transport box on our factory premises. If required, the emergency services of all fire brigades in the district of Goslar can transport the box to the scene of the emergency using the "Logistics" equipment vehicle (GW-L).

In BRANDSchutz/Deutsche Feuerwehr Zeitung (issue 09/2022, p. 812 ff.), District Fire Chief Uwe Fricke explains the key advantages of these special transport boxes for firefighting operations: they are available in various sizes from XS for e-bike batteries to XL for photovoltaic storage units, and they are designed for dry transport. This means that the battery does not have to be extinguished (keyword "contaminated extinguishing water"), but can burn out in the box.

Safe transport solutions for energy storage systems

All boxes in the StrainBox series have an integrated filter system that filters out a large proportion of the toxic gases. Harmful dust and particles are retained and the escape of solids, liquids and flames is prevented. Thanks to the integrated thermal management system, there is no critical temperature increase in the outer walls. Should the batteries inside break down, contamination in the area surrounding the box is prevented.

Properties

| Gas filter system | Mechanical resistance |

| No leakage of sparks and flames | Also for critical and defective lithium-ion batteriesbatteries |

| Pressure-resistant construction | Tested overall concept |

| No leakage of liquids and solids | Safe and durable locking mechanism |