Tips for planning fire protection measures

Fire protection in buildings with rail-bound intralogistics

It is a long road from developing the usage concept through to commissioning a logistics centre or a building with an intralogistics infrastructure.

An integrated concept is often impossible without experts or at least professional advice. Additional costs, in particular with respect to fire protection, can be avoided if specialists are involved at an early point in the design process. This article looks at important requirements relating to fire protection planning or rail-bound conveyor systems, and known problems and solution approaches.

Clarity about requirements

What are the statutory regulations and what needs to be taken into account when planning fire protection shields? Regardless of whether it is a new building or a renovation of an existing building, it is advisable checking the feasibility of the closures defined in the fire protection concept as soon as possible. Contacting a fire protection manufacturer is a good idea here.

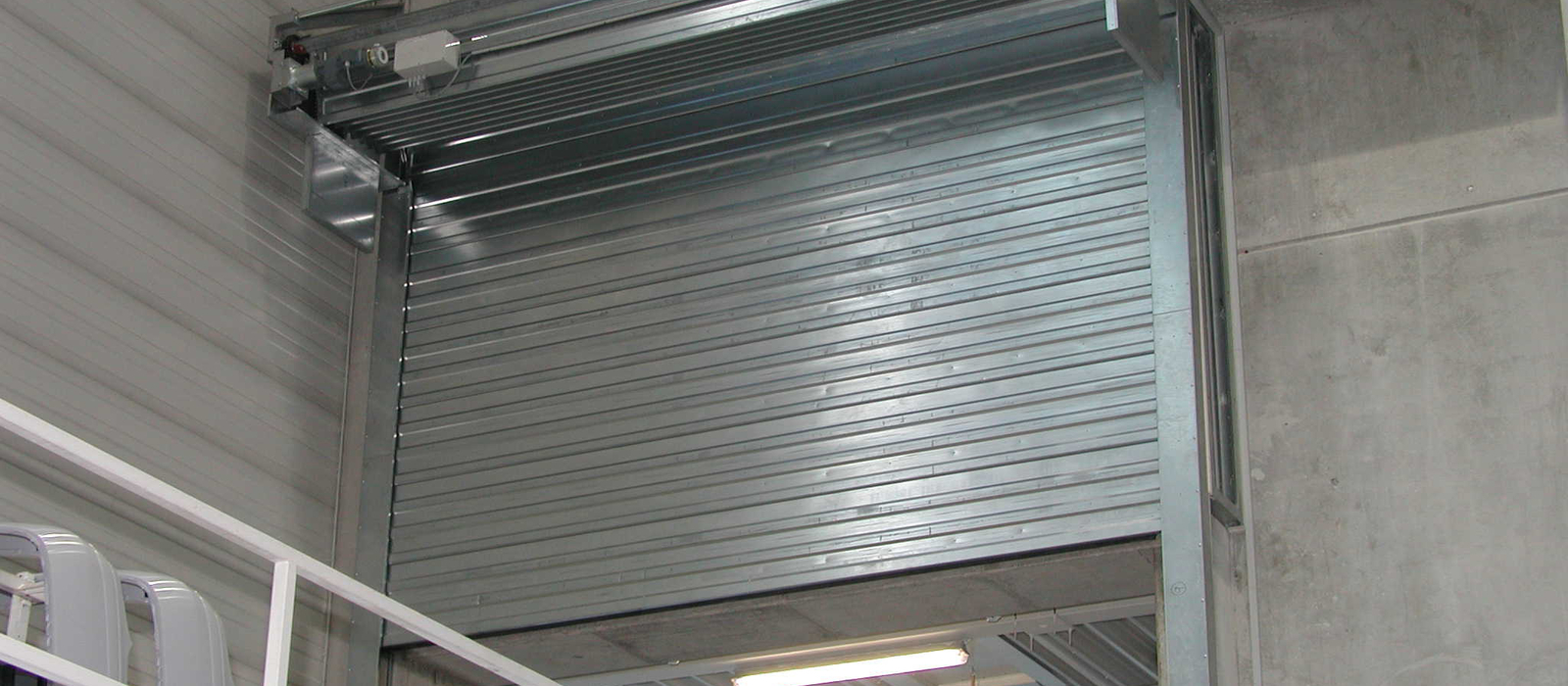

In principle, special and approved fire protection closures are required for openings in fire walls or ceilings used by rail-bound conveyor systems. The reason for this lies in the special risk associated with the opening that needs to be secured (transfer of fire loads to adjacent fire compartments) and also the higher mechanical wear of day-to-day conveyor operations. According to the Building Rules List, conveyor system closures are non-regulated building products and require either an approval from the building inspectorate or separate approval for specific cases. As practical enquiries have confirmed time and again, a normal sliding gate is not enough here.

Differences between national and European standards

According to the guidelines for the approval of conveyor system closures, the basic minimum classification for a closure of this kind in Germany is T 90 or EI 90 according to the European classification. Also, in Germany the continuous function of a closure must be verified up to at least 200,000 cycles, and according to European standards there will be 5 classification levels. There are also differences among the standards in terms which impact on the respectively stipulated proof of usability. For instance, there are differences between the fire resistance test according to the DIN 4102 and the harmonised test procedures of the European standard EN 1366-7. Higher pressure levels in the fire chamber and other measuring elements can limit the usability of a closure. Therefore, check whether the stated T-classification of a closure is also adequate as proof of usability in the respective EU country where the product is used.

What shielding variants for what opening?

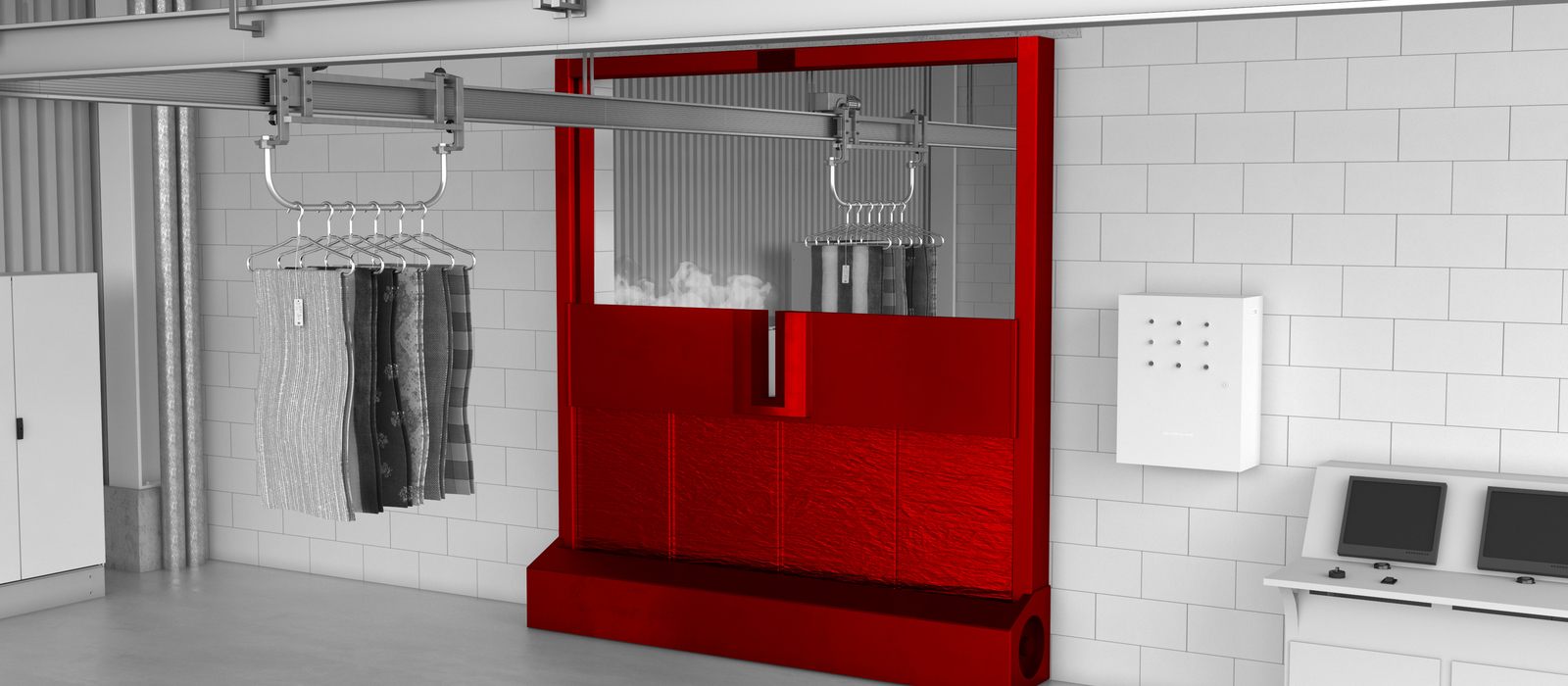

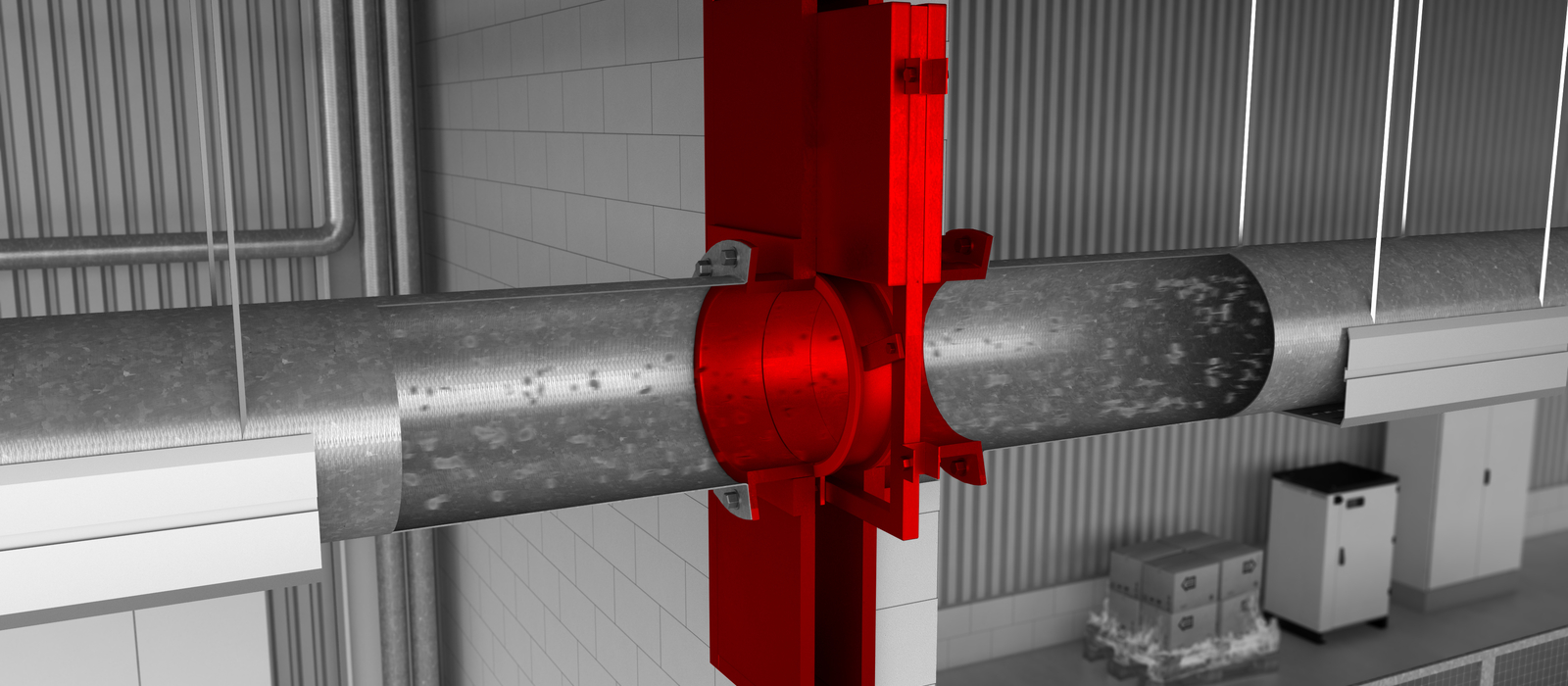

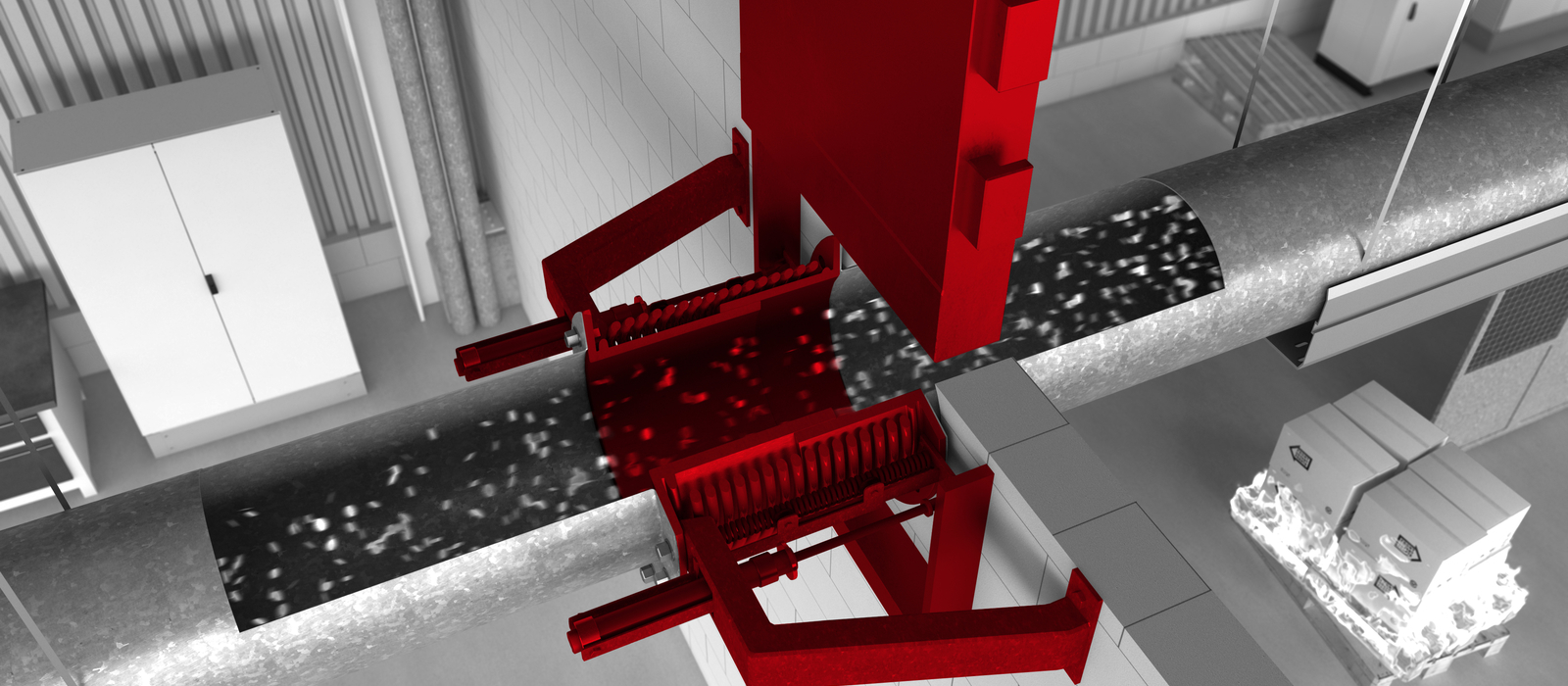

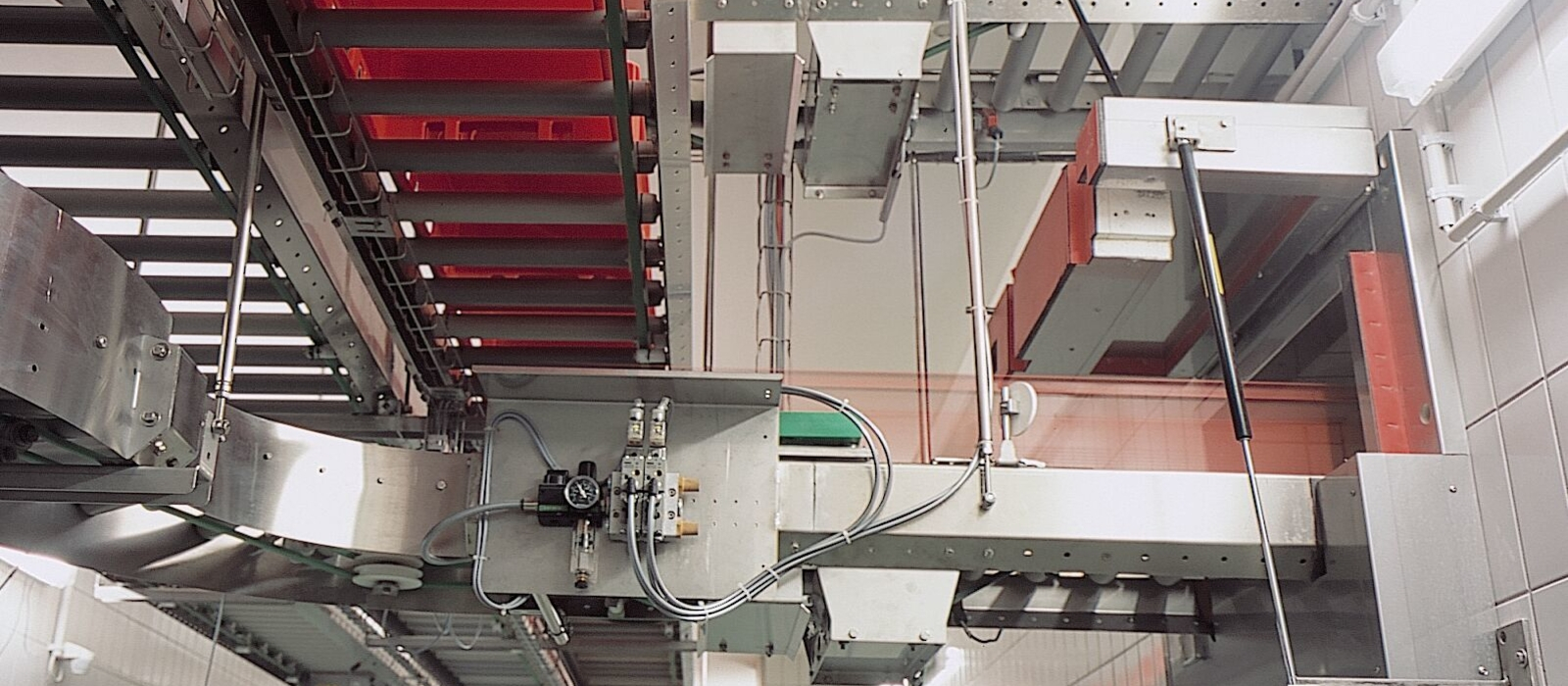

In principle, modern conveyor system closures will offer a solution for almost any needs. Neither the closing direction or the space requirements in the opening area nor the type of conveyor technology (interrupted, continuous, rising etc.) generally pose a problem. If a standard solution is not possible, various customised solutions are possible. Conveyor system closures come in a wide range of shapes and sizes. Depending on the space available at the installation site, dampers, valves or even textile constructions are available. Depending on the size of the opening that needs to be closed, special sectional gates can also be used to close conveyor systems. The choice of fire protection system primarily depends on the conveyor equipment used. The classic shielding option is often a damper system because this standard construction can usually be realised for most conveyor systems and is relative cost-effective. However, here the space requirements of the opened damper blade in the parked position need to be taken into account regardless of whether or not this moves horizontally or vertically. if the required space next to, below or above the opening is not planned in or is not available, alternatives will need to be sought. However these are often more expensive or require more space (e.g. valve constructions). Extra design effort beforehand may however be justified if it saves costs for the fire protection measures. Another aspect is the quality of the wall. This literally plays a crucial role because if it is not structural sound enough, (e.g. lightweight walls), additional supports will be required for the closure.

Topic: emergency power

Control systems and clearance equipment

DIBt-approved braking system control units are stipulated for fire protection closures as part of rail-bound conveyors. These ensure that the closing area is always kept clear when closures are used that are kept open by brake systems. This is based on the smooth interplay of the fire protection components and the control systems of the conveyor system. Likewise, functions such as the emergency-off, emergency power supply or hand trigger need to be taken into account. A pre-requisite for the safe closing of an opening is also a closing area that it is free of the conveyed materials. The so-called problem-oriented clearance of a closing area, also in the event of a power failure, depends on the type and design of the conveyor equipment and the conveyed goods themselves.

Summary: Integrate fire protection into the construction phase at any early stage

Try to avoid customised solutions and reduce the assembly times! The sooner the fire protection requirements are clear, the sooner they can be incorporated into the construction phase. This saves time and money, because often work on implementing fire protection measures is commenced far too late. Difficult installation conditions as a result of building-related limitations or parallel work then prolong the assembly time and ultimately the costs for installation. And if no standard solution can then be installed, expensive customised solutions will be required. Likewise, the position of switch cabinets and control systems and also the cable routes should be taken into account. Here, too, additional costs for material and installation work can be avoided.

Obviously, money should not be saved when it comes to fire protection, and anyone who does so is cutting corners which can have expensive consequences. However, early consideration of building-related fire protection measures will reduce unnecessary additional costs.

Check the fire protection requirements stipulated by law with respect to the fire protection concept. Clarify the options available when selecting the fire protection closures. In some cases, you can opt for a less expensive standard solution instead of an expensive customised solution. Also note what conveyor equipment is planned, what space you have available at the installation site and the quality of the walls. Plan the building work early on so that the installation time can be reduced thanks to the good assembly conditions.