Product description

The textile horizontal fire protection curtain for ceiling openings

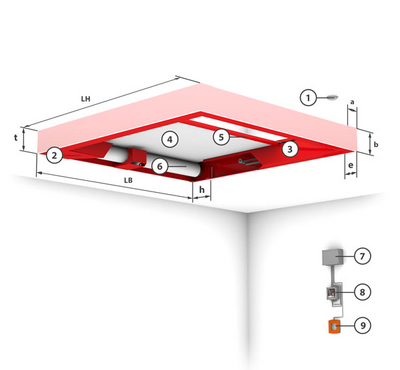

Even large ceiling openings that required a wide area closure with extensive drop length can be optimally protected against the effects of fire with the Fibershield-H fire protection curtain. The system is characterised by its versatile mounting possibilities (below the ceiling, in the embrasure) and by its construction design. In the event of alarm, the system reliably closes by means of spring force without requiring an external power source.

|

Type |

Textile fire protection curtain |

|

Fabric |

Protex 1100-B1 • Protex 1100.1 A2 |

|

Verification |

UB III/B-08-016 • UB III/B-05-020 |

|

Closing direction |

from left to right • from right to left |

|

Fire resistance |

E 120 |

|

Closing cycles |

C |

|

System |

LB (m) |

LH (m) |

a (mm) |

b (mm) |

e (mm) |

t (mm) |

h (mm) |

|---|---|---|---|---|---|---|---|

|

Gas spring |

< 1.4 |

< 1.5 |

120 |

190 |

109 |

190 |

200 |

|

Gas spring |

< 4.5 |

< 2.9 |

120 |

190 |

109 |

190 |

190 |

|

Gas spring |

< 4.5 |

≥ 2.9 < 5 |

150 |

235 |

109 |

235 |

290 |

|

Gas spring |

≥ 4.5 < 30 |

≥ 2.9 < 5 |

150 |

235 |

225 |

235 |

320 |

|

Duplex |

< 20 |

≥ 2.9 < 8,5 |

160 |

80 |

355 |

274 |

355 |