Product description

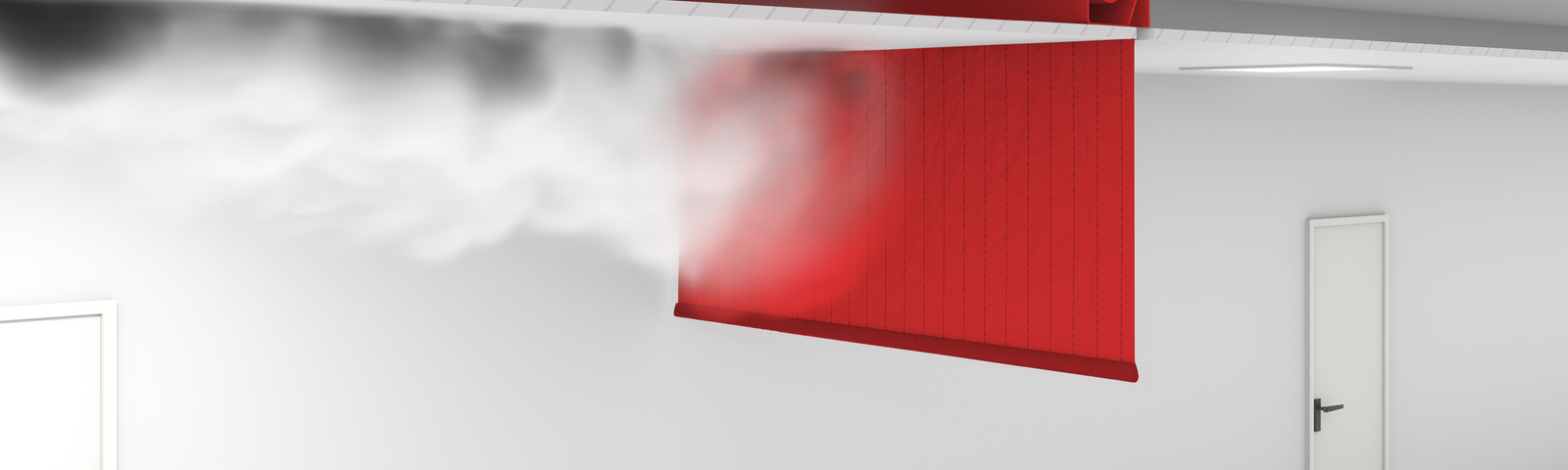

Prefabricated individual modules are lined up as a unit to form a complete smoke apron up to any lengthStandardised drop lengths up to 7 m Designed for the time class and temperature loads D = 600 °C As standard with "Gravigen" drive system i.e. closing without external energy, fire-resistant cables are not necessaryRobust drive systems, suitable for a high number of cycles up to 1,000 cycles with approved locking devices Modular mounting of the winding casings on top of or next to each otherConnected closing strip across all modules Also suitable (approved) for use as a floor-closing smoke apron and with lateral guide rail option.

|

Type |

Textile smoke apron |

|

Proof of usability |

UL 1784 |

|

Verification |

- Z - 56. 429 - 916 • CE according to DIN EN 12101-1 |

|

Closing direction |

From top to bottom |

|

Closing cycles |

1,000 cycles according to DIN EN 12101-1 |

|

Classification |

D 120 • DH 30 • Classification according to DIN EN 12101-1 |

|

Triggering |

Approved hold-open system • To be provided on site |

Downloads

|

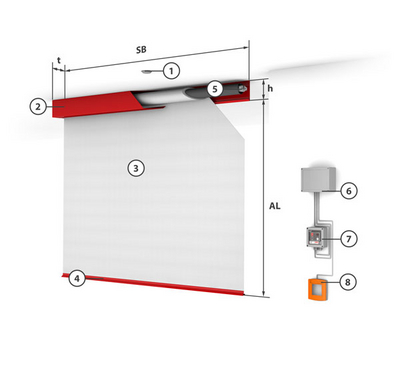

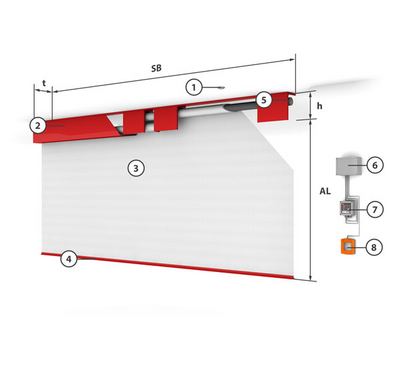

System width |

Drop length |

t |

h |

|---|---|---|---|

|

≤ 5 m |

≤ 4,5 m |

150 mm |

150 mm |

|

≤ 5 m |

> 4,5 m - ≤ 7 m |

185 mm |

185 mm |

|

> 5 m - ≤ 7 m |

≤ 4,5 m |

185 mm |

185 mm |

|

system width (SB) |

drop length (AL) |

t |

h |

|---|---|---|---|

|

> 7 m |

4,5 m |

160 mm |

280 mm |

|

> 7 m |

4,5 m - ≤ 7 m |

195 mm |

350 mm |

|

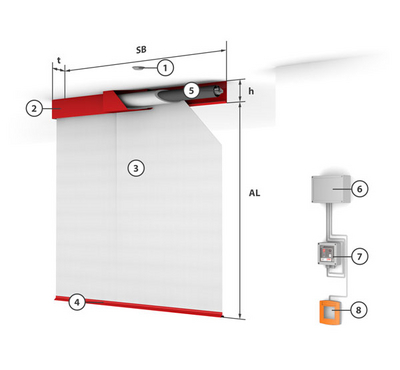

System width |

Drop length |

t |

h |

|---|---|---|---|

|

> 7 m |

4.5 m |

250 mm |

150 mm |

|

> 7 m |

4.5 m - ≤ 7 m |

320 mm |

185 mm |