Fire Multi Detector

| Main features | Monitoring of indoor, outdoor and dynamic areas (conveyor belts) | Daily and time-dependent detection parameters possible |

| Colour and intensity-based flame and smoke detection analyses result in a high detection rate and minimised false alarms. | Secure transmission of alarms with live still image into the SMC app enables visual review of incidents and improved situational awareness. | |

| The Fire Multi Detector has a built-in thermopile module that analyses temperatures in the detection area. | Neutralisation of the occurring harmful gases | |

| Internal recording enables the verification and analysis of events |

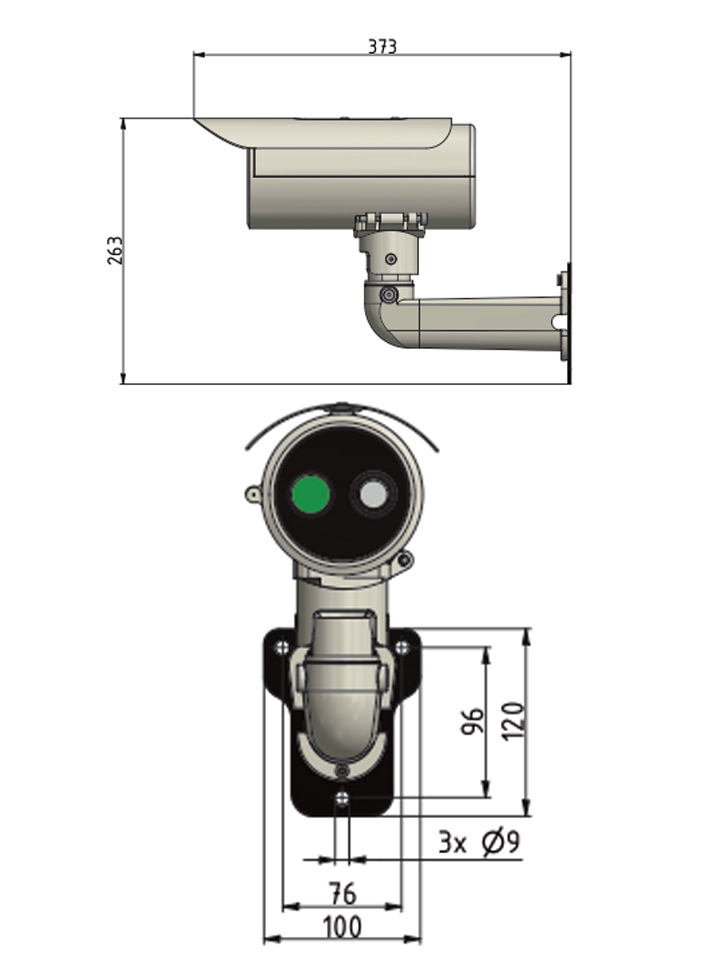

| Technical data | |||

| Dimensions L x B x H | |||

| Operating voltage | |||

| Power | |||

| Protection class | |||

| Operating temperature | Storage: -10 °C bis 70 °C | ||

| Humidity during operation | |||

| Weight | Approvals | ||

| Distance | |||

| Detection range optical | |||

| Detection range thermal | |||

| Resolution thermal | |||

| Temperature range | |||

| Monitoring area | 60 cm Fire: 290 m² | 60 cm Fire: 1.850 m² | |

| Detection | |||

| Image sensor | |||

| Automatic gain control AGC | |||

| WDR image enhancement | |||

| Signal-to-noise ratio | |||

| Minimum lighting | tion. Fire detection and temperature monitoring are fully functional in complete darkness. | ||

| Storage capacity | |||

| Available archiving formats | |||

| Alarms and relays | |||

| Central visualisation of detector images |

| Advanced contamination protection |

| Targeted deletion |

| Connection to existing fire protection systems |