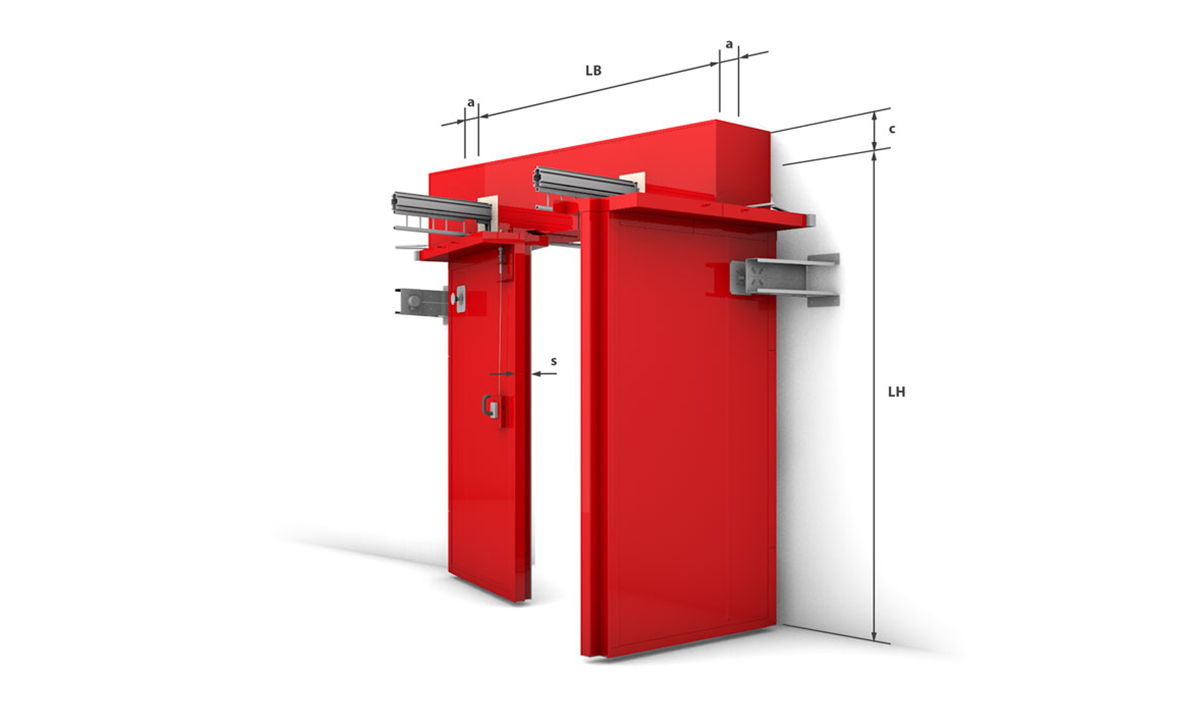

Product description

The particularly space-saving fire protection gate is designed as a double-leaf, swing-door closure. The two integrated, semi-circular collars encase the aluminium or steel rails passing through (including power rails) and seal them off. Thermal separation of the rail is not necessary. The gates can be opened manually and by motor. ECClos®-D is suitable for continuous belt conveyors, roller conveyors and suspension chain conveyors, but primarily for electrical overhead tracks, circular conveyors and Power&Free systems.