The Fibershield® Series-I system complies with the fire resistance classes EI₁ 30 - EI1 90 as well as EI2 30 - EI2 120 in accordance with EN 13501-2, is CE-marked and may be placed on the European market in sizes of more than 7 m width and approx. 5 m height in accordance with the harmonised product standard for fire and smoke protection closures EN 16034:2014 in conjunction with EN 13241:2003+A2:2016. The textile fire protection closure is the latest generation of thermally insulated fire protection curtains made by Stöbich.

Insulating fire curtain

Alternative to fire protection gates and doors

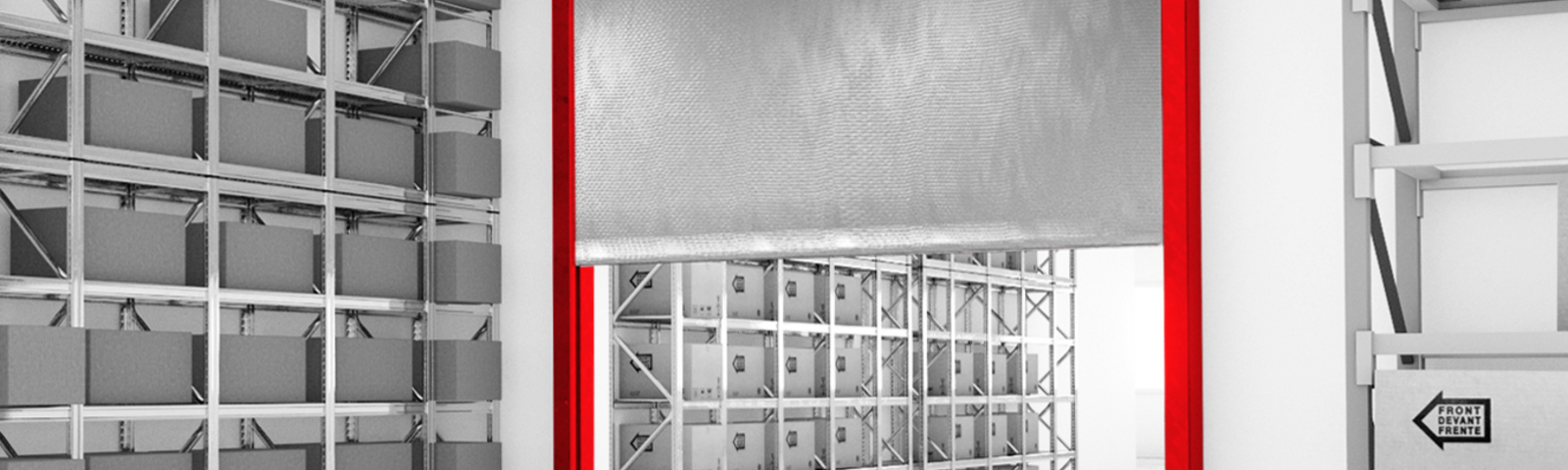

Buildings are divided into fire or smoke compartments to prevent the uncontrolled spreading of fire and smoke in case of fire. To prevent the fire from spreading to adjacent sections, the thermally insulating Fibershield® reliably closes even large wall openings. Thermally insulating means that not only the spreading of a fire as a result of flame penetration (classification "E") but also as a result of heat transfer (classification "I") is prevented. For planners, architects and facility operators Fibershield® provides a visually unobtrusive and economical fire protection solution. It is characterised by low space requirements, simple installation and great user benefits!

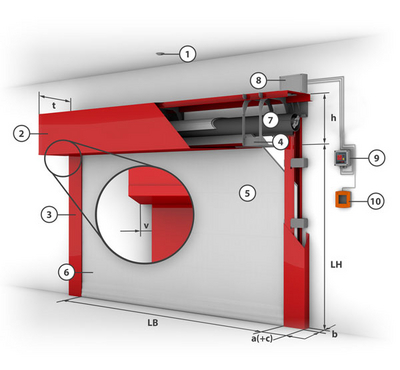

The closure has the winding kinematics of a rolling gate and requires little installation space above a wall opening. This way, the textile closure can be neatly integrated in suspended ceilings in an almost invisible way. The thin patented multi-layer fabric and the drive integrated into the winding tube allow for housing dimensions that require only half or a third of the space of a fire protection rolling gate.

Due to the patented lintel lock, the panels around the winding shaft can be dispensed with as an option. This way, the installation dimensions can be reduced even further. The multi-layer design of the fire protection curtain with its alternating insulating and cooling layers results in minimal material usage and thus a weight reduction in comparison to conventional designs. Thanks to its low weight and low installation space requirements, the system is ideally suited for modifying or retrofitting fire protection systems in existing buildings.

Creative freedom for architects and planners

In new buildings, the closures provide for unusual design options for the reliable closing of particularly wide openings in the event of fire. The main focus in the further development of Fibershield® was on easy installation. The guide rails are in plug-in design, without visible screw connections and can be harmoniously integrated into the building concept in terms of colour.

Benefits for facility operators

The enclosed space of a building should be used to its full potential. More storage space for pallets, more usable space for shelves or other fittings pays off in euros and cents. For conventional fire protection elements, it is usually necessary to provide room at the sides of the wall opening during daytime operation. With conventional fire protection doors, the open door leaves often have to be protected against collisions by an elaborate steel construction. The Fibershield® fire protection system is installed above a wall opening. The space required for the parking position in conventional elements can now be put to good use and the expenditure that would otherwise be incurred for protective structures and their maintenance is no longer an issue.