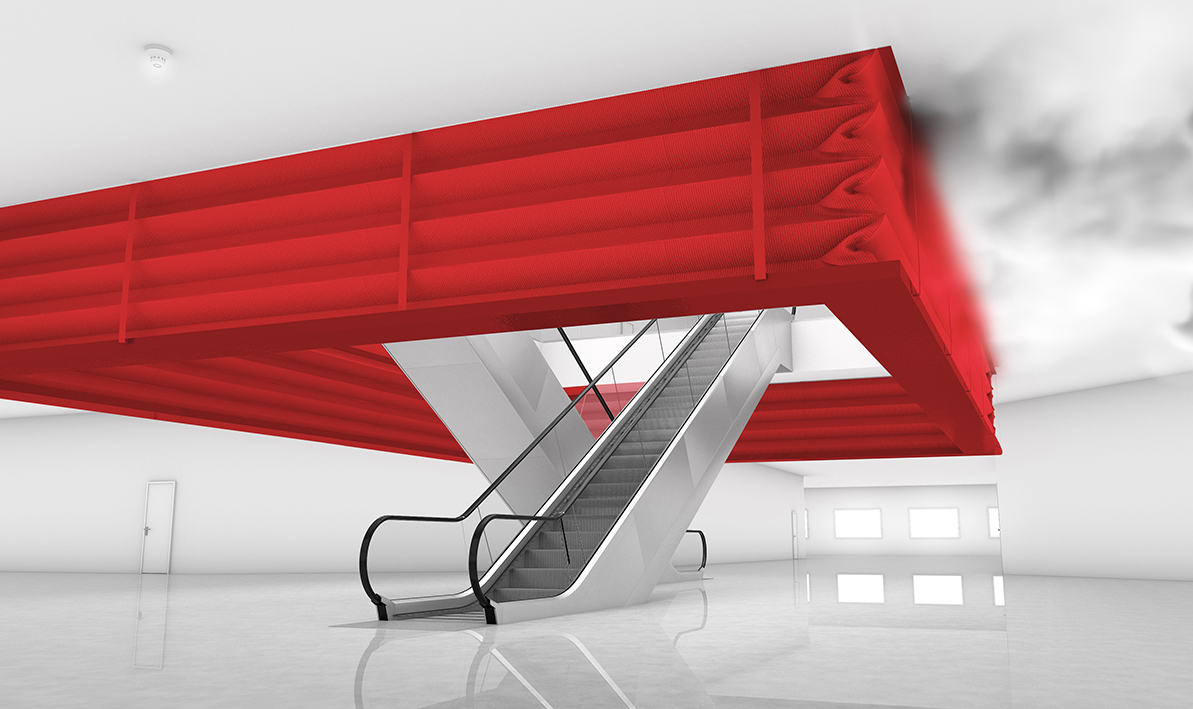

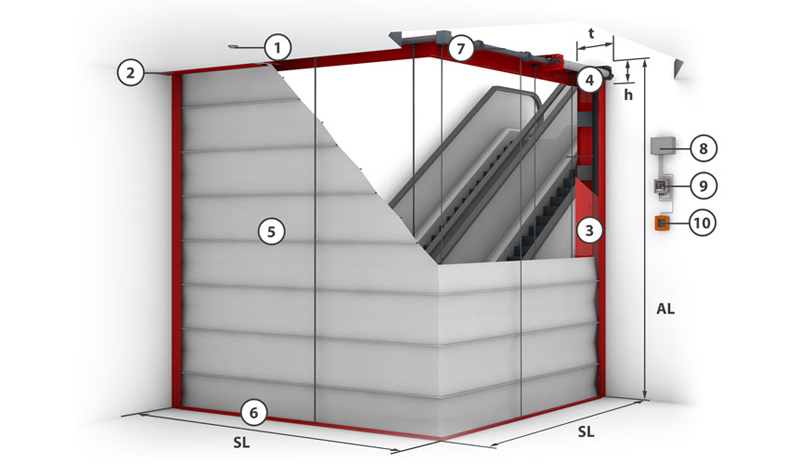

Product description

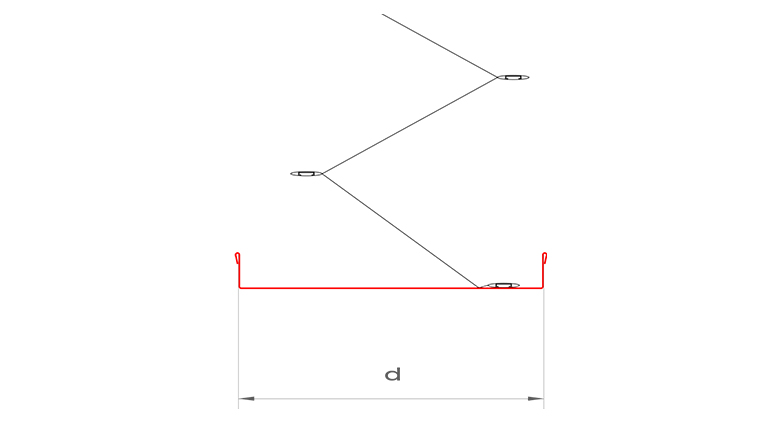

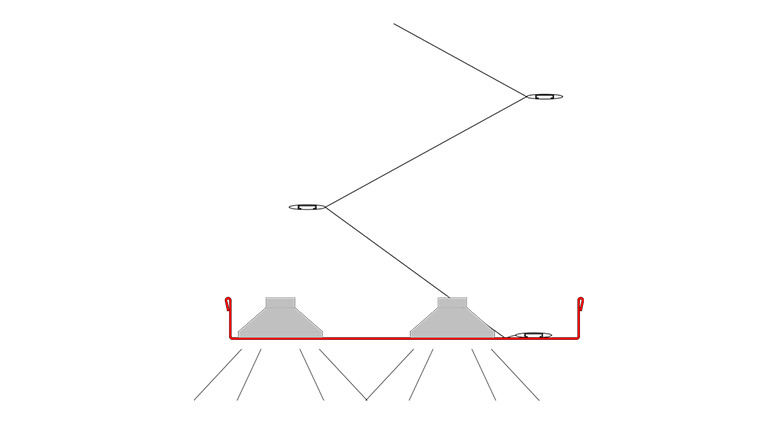

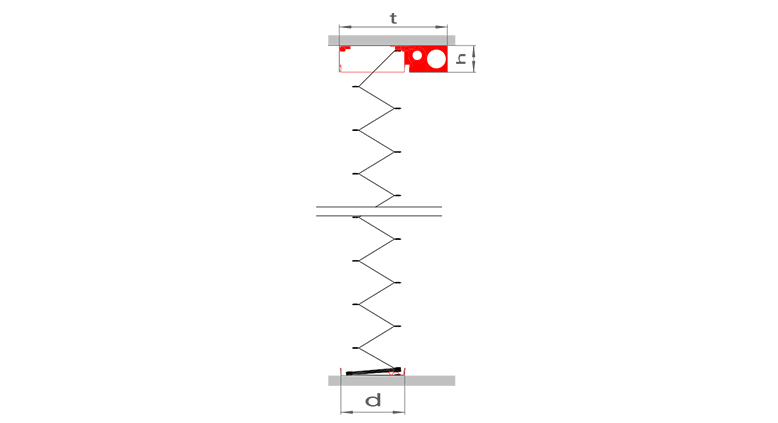

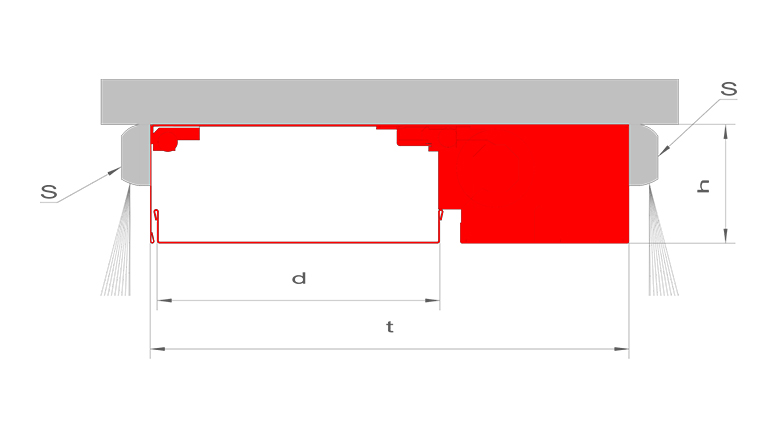

Rectangular and polygon-shaped floor space of the smoke apronEdge dimensions up to 16 m and drop lengths up to 6 mFor high time class and temperature loads D120 (600 ° C)No remaining openings – neither in the upper area nor in the cornersNo supporting structure required – absolutely tight even in high pressure load situationsLow installation height of the housing of approx. 125 mm and a drop length of < 3.0 mAs standard with "Gravigen" drive system i.e. closing without external energy, fire-resistant cables are not necessaryRedundant drive systems provide fall protectionAlso suitable (approved) for use as a floor-closing smoke apron.