SYSTEM: FIBERSHIELD® | SERIES FIBERSHIELD®-P

| Type of construction | Non-thermally insulating fire curtain |

| Proof | CE labelling in accordance with EN 16034:2014 in conjunction with EN 13241:2003+A2:2016 |

| Closing direction | from top to bottom |

| Fire resistance | E 30 - E 120 | EW 30 - EW 120 | tested according to EN 1634-1:2014+A1:2018 | classified according to EN 13501-2:2016 |

| Closing cycles | C0, C, C1, C2 | tested according to EN 12605:2000-08 and EN 12604:2017-12 | classified according to EN 13501-2:2016 |

| Fire behaviour of the textile | A2-s1, d0; B-s1, d0; E-d2 | tested according to ISO 1716 and EN 13823 or ISO 11295-2 | classified according to EN 13501-1:2018 |

| Environmental conditions | Not taken into account are special environmental conditions (e.g. humidity > 80 %, ambient temperature < 5 °C and > 40 °C, wind loads, etc.) |

| Visible surfaces | galvanised | RAL, smooth, semi-gloss, standard colour shade | NCS, standard colour shade |

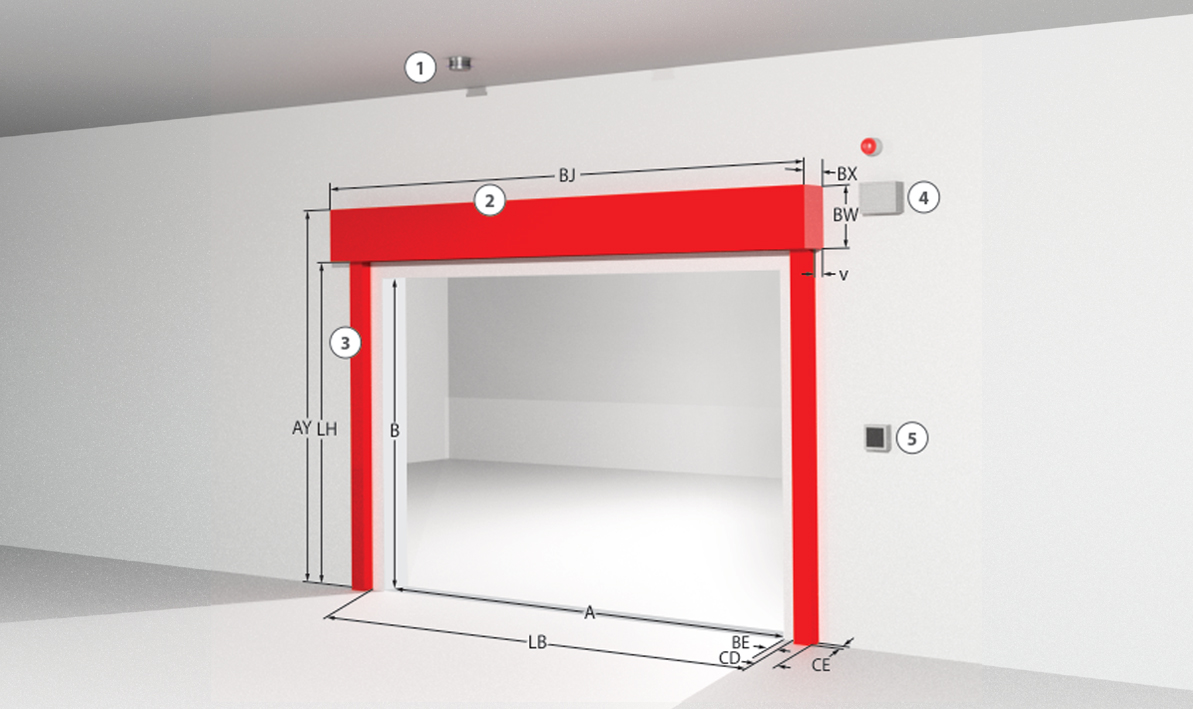

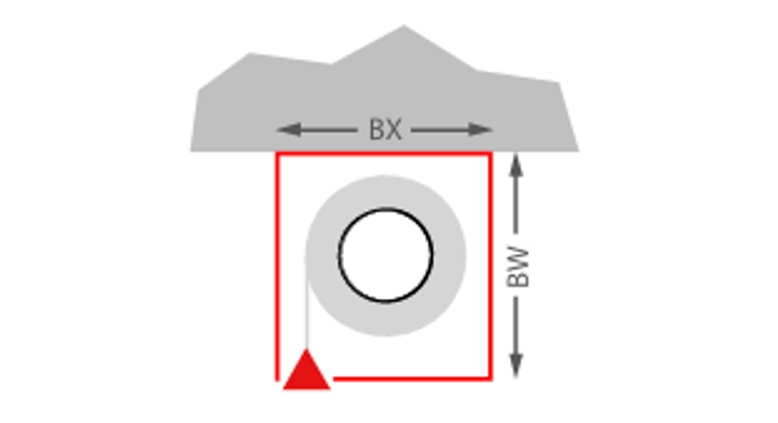

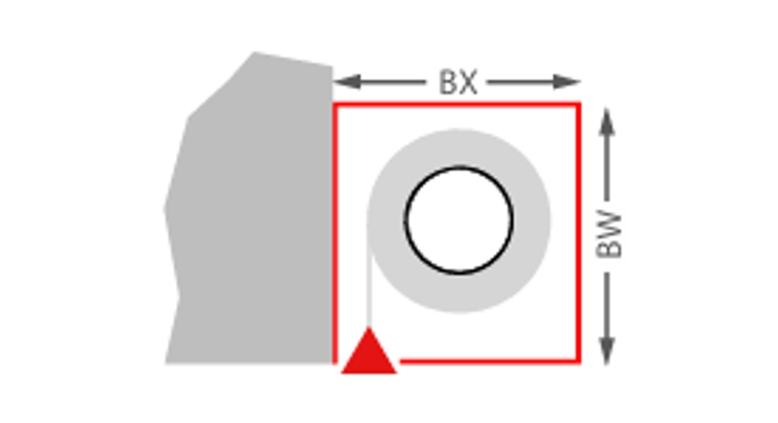

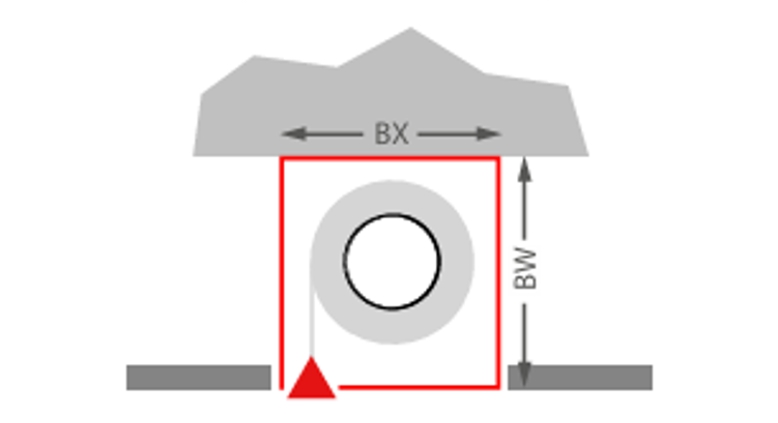

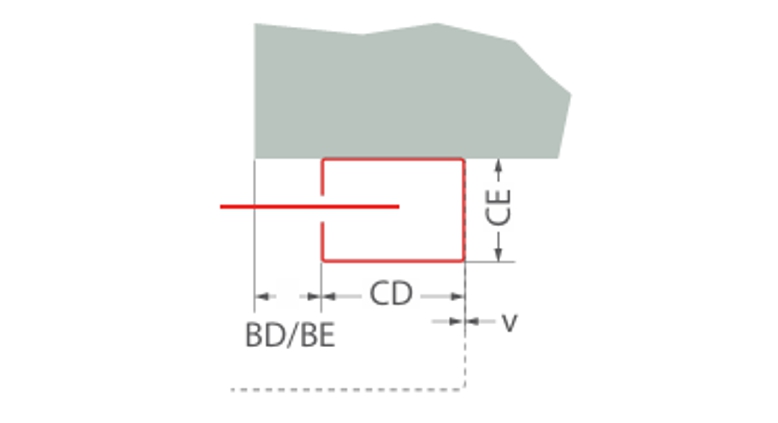

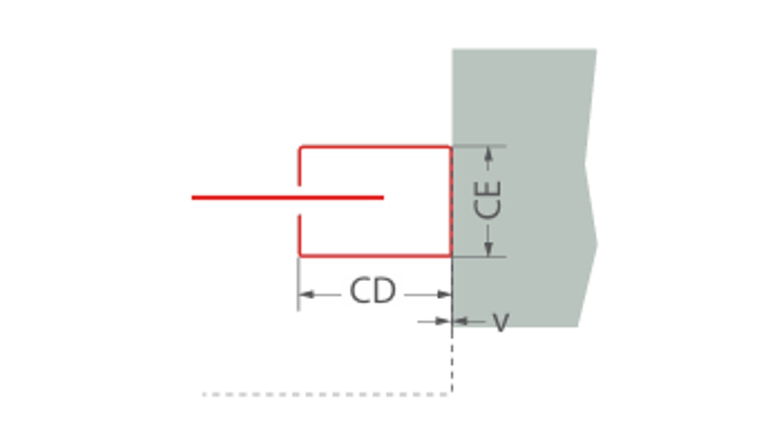

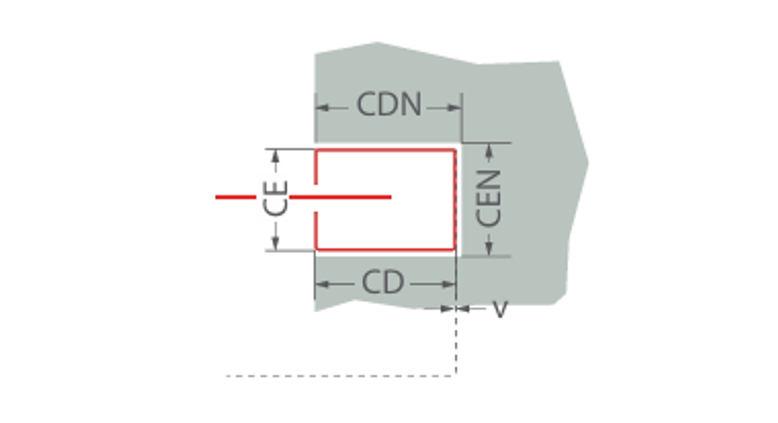

Size dimensions and system structure

Classification Fibershield®-P series

| Fire resistance class/ Classifications | Size* [LW x LH] in mm | Fabric | Wall thickness** in mm | Wrapped housing | Guide rails |

| E 30 | 11000 x 8000 | Protex 1100 1.A2 | 140 | Typ A, B, C | Typ 1, 2, 3 |

| E 60 | 11000 x 8000 | Protex 1100 1.A2 | 140 | Typ A, B, C | Typ 1, 2, 3 |

| E 90 | 11000 x 8000 | Protex 1100 1.A2 | 200 | Typ A, B, C | Typ 1, 2, 3 |

| E 120 | 11000 x 8000 | Protex 1100 1.A2 | 200 | Typ A, B, C | Typ 1, 2, 3 |

| EW 30 | 11000 x 8000 | Protex 1100 1.A2 | 140 | Typ A, B, C | Typ 1, 2, 3 |

| EW 30 | 12000 x 7500 | Heliotex 9 | 140 | Typ B, C, D, E | Typ 1, 2, 3 |

| EW 60 | 12000 x 7500 | Heliotex 9 | 200 | Typ B, C, D, E | Typ 1, 2, 3 |

| EW 90 | 12000 x 7500 | Heliotex 9 | 200 | Typ B, C, D, E | Typ 1, 2, 3 |

| EW 120 | 11000 x 3300 | Heliotex 12 | 200 | Typ B, C, D, E | Typ 1, 2, 3 |

| E 120 | 12000 x 7500 | Heliotex 9 | 200 | Typ B, C, D, E | Typ 1, 2, 3 |

| C0, C1 | 11000 x 4200 | Heliotex 9 | |||

| C0, C1, C2 | 7500 x 5000 | Heliotex 9 | |||

| C0, C1, C2 | 11000 x 9800 | Protex 1100 1.A2 |

The installation situation must comply with the building regulations of the country of installation. The fire resistance of a ceiling or wall supporting structure and the neighbouring components must at least correspond to that of the fire and/or smoke protection closure/fire and/or smoke protection curtain. Proof of the stability and serviceability of the neighbouring walls and components must be provided under general ambient conditions and in the event of fire. See also notes on the standard load-bearing structure in EN1366-7:2004 or EN1363-1:2020. The fire protection system must not be subjected to any additional load other than its own weight, even in the event of fire.

* Deviations from size dimensions on request

** Tested wall types according to the installation instructions